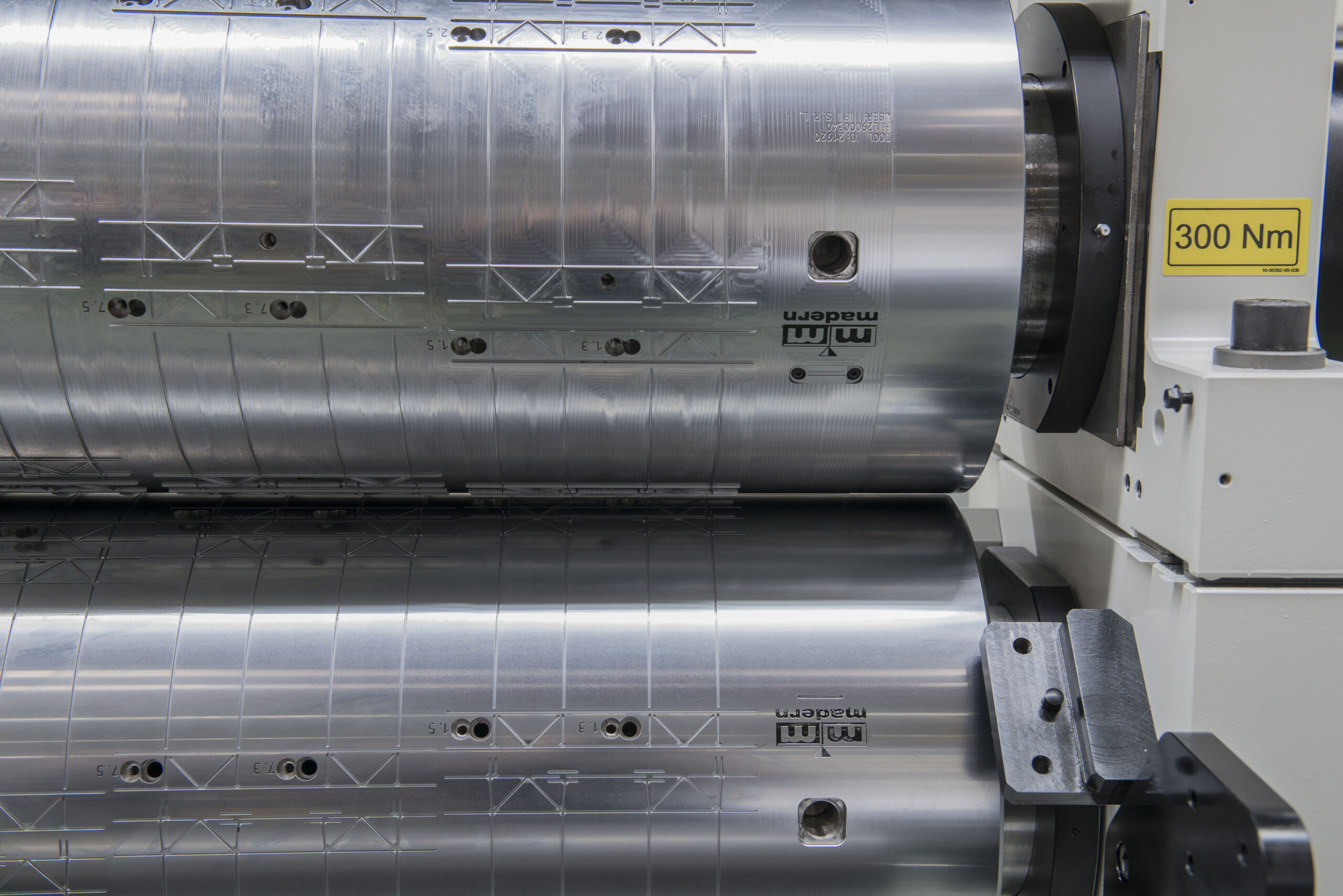

– With our sophisticated CNC machine park we are able to supply a wide range of rotary tooling. From a web width of approximately 500 mm up to 1750 mm and a diameter from approximately 180 mm up to 650 mm with a maximum weight of 5.000 kg. (cylinder dimensions outside this range upon request) Due to higher web speeds and different board grades, we are continuously looking to improve the performance of our rotary tools. We can manufacture our rotary tooling suitable for any rotary die cutter including of course our own Rotary Die Cutters.

Our cutting, creasing, embossing and punching tools are used in many different applications for the packaging industry, such as: tobacco packaging, liquid packaging, general folding cartons, nonwovens, plastic and sanitary productions.

The applied cutting technology, crush cut or MP dual knife (scissor cut), depends on the type of material to be cut, the shape of the product and the required performances, such as speed and life time of the tool. Madern can offer either technologies or a combination of both in one and the same tool.

With the different in-house manufacturing technologies we can offer a wide range of cutting, creasing and embossing tools, such as:

Madern dies are available in different type of tool- or PM steels. Depending on the specifications of the dies, special hardening treatments (laser or traditional hardening) or surface treatments (PVD or chrome-plate coatings) can be applied.